Your cart is currently empty!

Made When Ordered

Production Time: 5 days

The AF-N-R-10-ME40-18-15 will be automatically added to our production queue when it is ordered.

PRICE : $161.69(USD)

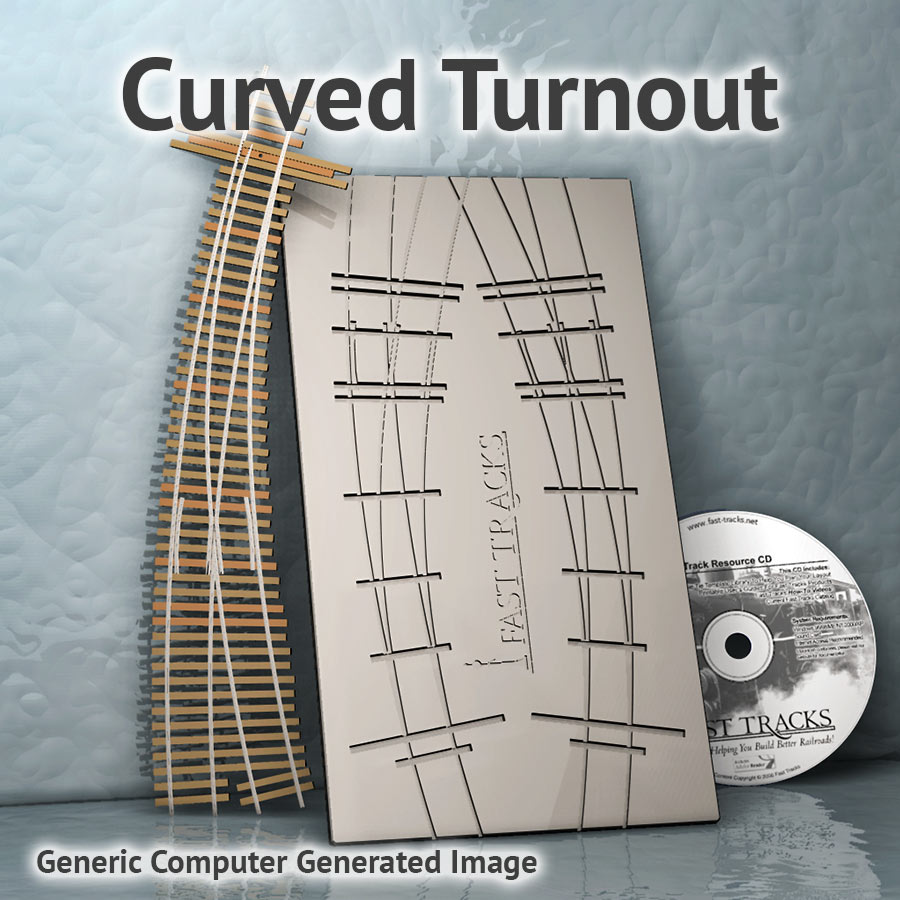

There is never enough space on any model railroad to fit in everything we want. But working some curved turnouts into your design will go a long way to giving you some extra space! Commercial curved turnouts are notoriously troublesome. Curved turnouts built using Fast Tracks tools operate trouble-free as they can hold the high tolerances needed for a smoothly running curved switch.

We have spent a lot of time determining the most popular combination of radii on our line of N curved turnout fixtures. Our curved turnout fixtures are designed around the "bent turnout" principle; that is, we've started with a standard #10 straight turnout and, using some sophisticated CAD software, "bent" it to an outside radius of 18"R (457.2mm). The inside radius of 15"R (381mm) is a product of that process. As the inside radius comprises three different radii, we've calculated an average radius from those sizes and stated them as the inside radius. It is safe to rely on that number as an accurate inside radius in your track planning.

Hand laying your own N #10 code 40, 18" outside radius and 15" inside radius (457.2mm/381mm) curved turnouts is not as hard as you might think! Tools and technology designed and manufactured by Fast Tracks now make it possible for you to build your own high-quality, NMRA compliant curved turnouts. Build curved turnouts that not only look great but will eliminate track-related derailments and frustration. Fast Tracks assembly fixtures will help you build high-quality hand laid track that:

- Is Highly Accurate - Build curved turnouts that stay in perfect gauge - permanently

- Performs Perfectly - Eliminates track related derailments

- Is Economical - Build hundreds of curved turnouts with one fixture

- Is Easy To Build - No special skills are needed

- Can Be Built Quickly - Build a curved turnout in less than an hour!

- Looks Great! - Get results that rival even the most experienced modelers

- Lets You Work in Comfort - Build trackwork at your workbench

- Is NMRA Compliant - Will work with any NMRA compliant equipment

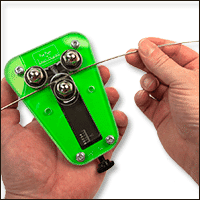

Each assembly fixture can be used to build right or left hand N #10 code 40, 18" outside radius and 15" inside radius (457.2mm/381mm) curved turnouts. Using Fast Tracks tools and supplies, building curved turnouts is not much different from building straight turnouts and does not require any special skills. The only real difference is that the rail is curved, so you may want to consider purchasing one of our Rail Rollers, making it very easy to bend rail into smooth and consistent radiuses.

As Fast Tracks curved turnouts are straight turnouts that have been curved, the frog is also curved, but still, a standard #10 turnout, which means that you can use our standard PointForm tool to construct the frog. If you order a Fast Tracks assembly fixture, we highly recommend that you consider including the PointForm and StockAid points filing tools. This will make the construction of the switch and frog points much easier. You may also consider including some CopperHead PC Board ties and our matching Laser Cut QuickSticks to your order. Unlike ready-to-run turnouts, the stated radiuses for Fast Track's curved turnouts are very accurate.

Click on the Supplies Tab above to add additional items needed to build curved turnouts to your order. Try our Supplies Calculator to determine the consumable items you will need for your trackwork project.

Failure to pre-bend the rail for curved trackwork will result in solder joint failure over time!

Below is a cross-reference chart showing which rail other than Micro Engineering is compatible with our fixtures.

| Fixture Cut For | Rail Size | Compatible With |

|---|---|---|

| ME Code 55 | Code 55 | Atlas Code 80 |

| ME Code 55 | Code 55 | Atlas Code 55 |

| ME Code 55 | Code 55 | Peco Code 80 |

| ME Code 70 | Code 70 | ME Code 83 |

| ME Code 70 | Code 70 | Peco Code 83 (IL-115) |

| ME Code 70 | Code 70 | Peco 75 |

| ME Code 70 | Code 70 | Pilz Code 83 |

| ME Code 70 | Code 70 | Tilig 83 |

| ME Code 83 | Code 83 | ME Code 70 |

| ME Code 83 | Code 83 | Peco Code 83 (IL-115) |

| ME Code 83 | Code 83 | Peco 75 |

| ME Code 83 | Code 83 | Pilz Code 83 |

| ME Code 83 | Code 83 | Tilig 83 |

| ME Code 100 | Code 100 | Walthers Code 83 |

| ME Code 100 | Code 100 | Roco Line 83 |

| ME Code 100 | Code 100 | Atlas Code 83 |

| ME Code 100 | Code 100 | Atlas Code 100 |

| ME Code 125 | Code 100 | C & L 125 |

| ME Code 148 | Code 100 | Right-O-Way 148 |

Track Building Supplies

You have added supplies to the cart, but not the assembly fixture needed to build trackwork. Don’t forget to add the fixture to your order!

In addition to an assembly fixture, you also need to order additional supplies.

Enter the number of switches you want to build in the top box and then click the Calculate Quantities button to determine how many products you should order.

You added track building supplies and tools to the cart, but not the assembly fixture needed to build trackwork.

Do you want to add a N Scale, #10, 18R/15R Curved Turnout Fixture for Micro Eng 40 Rail to your order?

No ThanksYou must be logged in to post a review.

| PARAMETER | VALUE | DETAILS |

|---|---|---|

| Default Turnout Length | 8.9" (226 mm) | This is the length of the turnout on the QuickSticks. Measured from end tie to end tie. |

| Minimum Turnout Length | 6.7" (170 mm) | This is the shortest possible turnout length. Measured from the end PC board tie to end PC board tie. |

| Diverging Route Angle | 5.71 (Decimal) 5°/42'/36"(D/M/S) 1:10 (Ratio) | Decimal = Frog angle in decimal degrees D/M/S = Deg/Min/Sec Ratio = Frog angle expressed as a ratio |

| Outside Radius | 18" (457 mm) | The radius of the outside route of a curved turnout. |

| Inside Radius | 15" (381 mm) | The approximate radius of the inside route of a curved turnout. |

| Tie Spacing (Prototype) | 20" (508 mm) | Tie spacing center of tie to center of tie. |

| Tie Size (Model) | L - 0.64" (16 mm) W - 0.06" (2 mm) H - 0.04" (1 mm) | The actual size of the tie. |

| Tie Size (Prototype) | L - 8.5' (2.6 m) W - 9"(229 mm) H - 7" (178 mm) | The original tie size that the model was based on. |

| Track Gauge | 0.36" (9 mm) | The distance between the stock rails. |

| Size | L - 8" (203 mm) W - 3" (76 mm) H - 0.25" (6 mm) | The physical size of the product |

| Weight | 0.65 lbs (0.295 kg) | |

| Material | 6061 Aluminum |

Building Turnouts Using Fast Tracks Assembly Fixtures

This fully illustrated document provides complete details for building switches using Fast Tracks tools & supplies. These instructions apply to Turnouts, Wyes & Curved Turnouts in all scales and include essential information for building any fixture-built trackwork.

Building A Stub Switch Using A Fast Tracks Assembly Fixture.

Do you already own a Fast Tracks Assembly Fixture? Then you can use the same fixture and tools you have now to build a stub turnout with QuickSticks and PC Board ties.

Using The PointForm Tool To Build Frog & Switch Points

We offer a number of different types of PointForm tools. This document provides general instructions on how to use a PointForm tool. These instructions apply to all PointForm tools.

Filing The Stock Rail With The Fast Tracks StockAid Filing Tool

Using the StockAid tool to remove the base of the stock rail in a turnout. These instructions apply to all sizes of StockAid tools.

Completing Switches Using Fast Tracks QuickSticks

This Builders Guide details how to complete building your switch using QuickSticks laser-cut wood ties.

Building A Turnout Switch Using Fast Tracks Tools

Step-by-step videos demonstrate how to build a complete switch using a Fast Tracks assembly fixture, PointForm, StockAid, and other tools.

Building a curved turnout with Fast Tracks Tools

Watch along as we build a complete On30 curved turnout from start to finish.

Using The Fast Tracks PointForm Tool To Build Switchpoints

The PointForm tool is not only used to file Frog points. It can also be used to file perfect switch points as well. Here is how it works.

Using The Multi-Brush Solder Paste Applicator For Soldering Trackwork

The Multi-Brush makes applying just he right amount of solder flux quick and easy. You will also find it a handy brush to have around for general model construction as well.

Using The 35W Weller Soldering Iron For Model Railroad Trackwork

Using the right soldering iron to solder trackwork is critical to success. We recommend the 35 watt Weller pencil type soldering iron with the ST7 conical shaped soldering tip. Watch along as we demonstrate how to get the most from this soldering equipment.

Bending & Straightening Rail With The Fast Tracks Rail Roller

Bending rail into long smooth curves for curved trackwork can be challenging. The Fast Tracks Rail Roller tool makes this difficult job quick and easy. Plus it can straighten bent rail as well. This video shows you how it works.

Solder Overview

Detail about the solder supplied by Fast Tracks for building all types of model trackwork.

Cutting Rail Gaps

We thought you might like this short video we produced showing the process of cutting rail gaps to isolate the frog in a Fast Tracks turnout electrically. This step is critical and can not be skipped. Otherwise, the track will have a dead short and can not be powered.

Using The Fast Tracks PointForm Tool To Build Frogpoints

Building highly accurate frogpoints is made fast and simple with the Fast Tracks PointForm tool. Here is a detailed demonstration showing you how it works.

Using The StockAid Tool To File The Base Of The Stockrail

Video demonstration on using the StockAid tool to remove the base of the stockrail.

Fast Tracks Video Channel

Visit our growing collection of track building demonstration videos

Fast Tracks Knowledge Base

In addition to an extensive Q&A section, we also offer a full library of track building documents.

Reviews

There are no reviews yet.