Your cart is currently empty!

1 In Stock

We can ship the AF-HO-T-5-ME83 immediately. If you order more than what we have available, we will hold your order and add additional units required to our production queue. The lead time for this product is shown above.

PRICE : $161.69(USD)

1 in stock

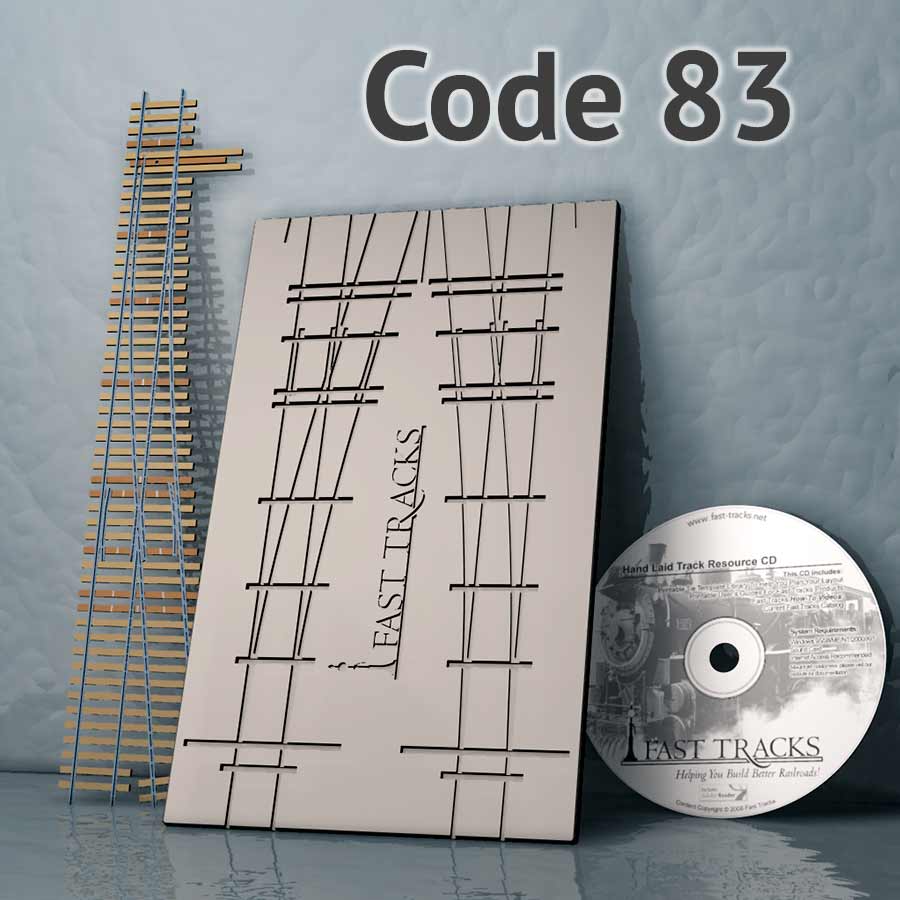

Hand laying your own HO scale #5 Turnouts is not as hard as you might think! Tools and technology designed and manufactured by Fast Tracks make it possible for you to build your own high-quality, NMRA compliant turnouts.

With this HO, #5 turnout assembly fixture, you can build an unlimited supply of turnouts when you need them, at the comfort of your workbench, in about an hour. Fast Tracks, the turnout assembly fixture system developer, has been producing its line of extremely precise tools since 2003. We've worked out all the details to make building trackwork as easy as possible, so now any modeler can produce the most accurate, best-looking, and smoothest operating trackwork available.

Build turnouts that not only look great but will eliminate track related derailments and frustration.

How Will Fast Tracks Assembly Fixtures Help?

Fast Tracks assembly fixtures will help you build high-quality hand-laid track that:

- Is Highly Accurate - Build turnouts that stay in perfect gauge - permanently

- Performs Perfectly - Eliminates track related derailments

- Is Economical - Build hundreds of turnouts with one fixture

- Is Easy To Build - No special skills are needed

- Can Be Built Quickly - Build a turnout in less than an hour!

- Looks Great! - Get results that rival even the most experienced modelers

- Lets You Work in Comfort - Build trackwork at your workbench

- Is NMRA Compliant - Will work with any NMRA compliant equipment

Each assembly fixture can be used to build right or left Turnouts.

To finish off your trackwork, add our matching QuickSticks to your order. These laser-cut wood ties will make finishing turnouts a snap, glue the complete set of pre-cut ties to the turnout, and it's done! We also offer traditional single piece wood turnout ties as well.

If you order a Fast Tracks assembly fixture, we highly recommend that you consider purchasing matching PointForm and StockAid filing tools. This will make the construction of the switch and frog points much easier.

In addition to code 83 rail, you will also need to purchase matching 0.0625" (1.6mm), (7 scale inches) thick, CopperHead PC board turnout ties manufactured by Fast Tracks.

Click on the Supplies Tab above to add additional items needed to build turnouts to your order. Try our Supplies Calculator to determine the consumable items you will need for your trackwork project.

Below is a cross-reference chart showing which rail other than Micro Engineering is compatible with our fixtures.

| Fixture Cut For | Rail Size | Compatible With |

|---|---|---|

| ME Code 55 | Code 55 | Atlas Code 80 |

| ME Code 55 | Code 55 | Atlas Code 55 |

| ME Code 55 | Code 55 | Peco Code 80 |

| ME Code 70 | Code 70 | ME Code 83 |

| ME Code 70 | Code 70 | Peco Code 83 (IL-115) |

| ME Code 70 | Code 70 | Peco 75 |

| ME Code 70 | Code 70 | Pilz Code 83 |

| ME Code 70 | Code 70 | Tilig 83 |

| ME Code 83 | Code 83 | ME Code 70 |

| ME Code 83 | Code 83 | Peco Code 83 (IL-115) |

| ME Code 83 | Code 83 | Peco 75 |

| ME Code 83 | Code 83 | Pilz Code 83 |

| ME Code 83 | Code 83 | Tilig 83 |

| ME Code 100 | Code 100 | Walthers Code 83 |

| ME Code 100 | Code 100 | Roco Line 83 |

| ME Code 100 | Code 100 | Atlas Code 83 |

| ME Code 100 | Code 100 | Atlas Code 100 |

| ME Code 125 | Code 100 | C & L 125 |

| ME Code 148 | Code 100 | Right-O-Way 148 |

Track Building Supplies

You have added supplies to the cart, but not the assembly fixture needed to build trackwork. Don’t forget to add the fixture to your order!

In addition to an assembly fixture, you also need to order additional supplies.

Enter the number of switches you want to build in the top box and then click the Calculate Quantities button to determine how many products you should order.

You added track building supplies and tools to the cart, but not the assembly fixture needed to build trackwork.

Do you want to add a HO Scale, #5 Turnout Assembly Fixture for Micro Engineering 83 Rail to your order?

No Thanks12 reviews for HO Scale, #5 Turnout Assembly Fixture for Micro Engineering 83 Rail

You must be logged in to post a review.

| PARAMETER | VALUE | DETAILS |

|---|---|---|

| Default Turnout Length | 9.9" (251 mm) | This is the length of the turnout on the QuickSticks. Measured from end tie to end tie. |

| Minimum Turnout Length | 7.2" (183 mm) | This is the shortest possible turnout length. Measured from the end PC board tie to end PC board tie. |

| Diverging Route Angle | 11.31 (Decimal) 11°/18'/36"(D/M/S) 1:5 (Ratio) | Decimal = Frog angle in decimal degrees D/M/S = Deg/Min/Sec Ratio = Frog angle expressed as a ratio |

| Diverging Route Radius | 26" (660 mm) | The minimum radius in a straight turnout. |

| Tie Spacing (Prototype) | 20" (508 mm) | Tie spacing center of tie to center of tie. |

| Tie Size (Model) | L - 1.17" (30 mm) W - 0.1" (3 mm) H - 0.0625" (2 mm) | The actual size of the tie. |

| Tie Size (Prototype) | L - 8.5' (2.6 m) W - 9"(229 mm) H - 7" (178 mm) | The original tie size that the model was based on. |

| Track Gauge | 0.66" (17 mm) | The distance between the stock rails. |

| Substitution Radius | 31" (787 mm) | The approximate radius that the diverging route of a turnout can be fit into. This calculation was made using the shortest possible turnout length measured from the edges of the PC board ties, not the wood ties. |

| Size | L - 10" (254 mm) W - 6" (152 mm) H - 0.25" (6 mm) | The physical size of the product |

| Weight | 1.441 lbs (0.654 kg) | |

| Material | 6061 Aluminum |

Building Turnouts Using Fast Tracks Assembly Fixtures

This fully illustrated document provides complete details for building switches using Fast Tracks tools & supplies. These instructions apply to Turnouts, Wyes & Curved Turnouts in all scales and include essential information for building any fixture-built trackwork.

Building A Stub Switch Using A Fast Tracks Assembly Fixture.

Do you already own a Fast Tracks Assembly Fixture? Then you can use the same fixture and tools you have now to build a stub turnout with QuickSticks and PC Board ties.

Using The PointForm Tool To Build Frog & Switch Points

We offer a number of different types of PointForm tools. This document provides general instructions on how to use a PointForm tool. These instructions apply to all PointForm tools.

Filing The Stock Rail With The Fast Tracks StockAid Filing Tool

Using the StockAid tool to remove the base of the stock rail in a turnout. These instructions apply to all sizes of StockAid tools.

Completing Switches Using Fast Tracks QuickSticks

This Builders Guide details how to complete building your switch using QuickSticks laser-cut wood ties.

Building A Turnout Switch Using Fast Tracks Tools

Step-by-step videos demonstrate how to build a complete switch using a Fast Tracks assembly fixture, PointForm, StockAid, and other tools.

Using The TieBreaker PC Board Tie Cutting Tool

Cutting each PC Board tie to the length you need for a turnout can be tedious and drawn-out. Here Tim demonstrates how the Fast Tracks TieBreaker tool speeds up the process, reducing the construction time for a turnout by as much as 30%!

Using The Multi-Brush Solder Paste Applicator For Soldering Trackwork

The Multi-Brush makes applying just he right amount of solder flux quick and easy. You will also find it a handy brush to have around for general model construction as well.

Using The 35W Weller Soldering Iron For Model Railroad Trackwork

Using the right soldering iron to solder trackwork is critical to success. We recommend the 35 watt Weller pencil type soldering iron with the ST7 conical shaped soldering tip. Watch along as we demonstrate how to get the most from this soldering equipment.

Solder Overview

Detail about the solder supplied by Fast Tracks for building all types of model trackwork.

Cutting Rail Gaps

We thought you might like this short video we produced showing the process of cutting rail gaps to isolate the frog in a Fast Tracks turnout electrically. This step is critical and can not be skipped. Otherwise, the track will have a dead short and can not be powered.

Painting Trackwork Slideshow

We are often asked if we have made a video on painting trackwork, and to date, we have not. Back in 2009, we produced a slideshow for MRH Magazine on how we finish turnouts, but it is no longer available from them, so we reproduced it and uploaded it here.

Making a Over Center Spring for Manual Turnout Control

A step-by-step instructional video on how to add a simple center over spring to a Fast Tracks (or other) turnout. With this simple spring, you can manually switch a turnout without needing any switch machine!

Using The Fast Tracks PointForm Tool To Build Frogpoints

Building highly accurate frogpoints is made fast and simple with the Fast Tracks PointForm tool. Here is a detailed demonstration showing you how it works.

Fast Tracks Video Channel

Visit our growing collection of track building demonstration videos

Fast Tracks Knowledge Base

In addition to an extensive Q&A section, we also offer a full library of track building documents.

Lynn Dobbs (verified owner) –

I've bought two of these (lost the first one) as well as a #6 and two other fixtures. With a little bit of care, I've made more than 40 turnouts that operate flawlessly. Even my first one even though it was a bit sloppy. The only issue is that I've had to slightly modify both #5 fixtures to slightly lengthen point rail groove where it meets the stock rail. The groove narrows so quickly that the point rail would have to stop at the throw bar. I made one that way and didn't care for the look.

Joel Guenther (verified owner) –

I need about 110 turnouts for my new HO layout. Commercial turnouts were too expensive and have quality &/or performance issues. The Fast Tracks method offeres a satisfactory solution to my needs, but requires my time and effort to fabricate - a good compromise. I just completed 45 #5 turnouts using code 83 ME weathered rail (a mistake - had to sand/grind off to permit soldering). Never having hand built turnouts before, I learned a lot in this process: 1) use unweathered rail; 2) always verify track with the official NMRA guage before and after soldering - I had problems with point and guard rails leaning causing gap issues & lots of resoldering; 3) use acid flux - wash using old tooth brush; 4) stock aid filing caused rail to bend upward - hard to fix this; 5) CopperHead pc ties seem too thin for use with FT template - leaves gap under rail, especially for throw bar use - shimming with duct tape in FT template pc tie channels may solve this problem; 6) apply ample Pliobond cement to wooden Quickties - light coat to rails - join after 5-10 min - heat with soldering iron along rail base flange to quick cure; 7) use ignition point file & Xacto knife to clean residual contact cement from points area; 8) Pre-fab all rail & pc tie pieces before beginning assembly - store pieces in labeled zip baggies. I also created a tool to utilize my Dremel with grinding disk to put accurate gaps in pc ties (I had trouble using triangle file to do this) - I need to create over 1500 gaps for my 110 turnouts - this tool is a life saver. I found that a learning experience is necessary to avoid the issues I had, but is well worth the effort to achieve economical and reliable turnouts with the Fast Tracks system. My remaining 55 turnouts (#6s, #8s, various curved sizes) will benefit from my experience. I am sold on the Fast Tracks process for making turnouts.

Richard Rafenstein (verified owner) –

The fixture is just as I expected, well made and accurate. Built a perfect #5 switch.

Ed Jameson (verified owner) –

I've used many of Fast Tracks products, and not found a clunker in the bunch. All very well designed, and extremely useful. In building my layout, the thing I most dreaded was building turnouts/switches; to my surprise, it's now my most enjoyable and satisfying activity in creating my dream layout (who'd a thought !). The Fast Tracks assembly fixtures (I've used the #5, #6, and #8 fixtures) make the building process both reliable and enjoyable. Thank you Fast Tracks !

Rick Schonfelder (verified owner) –

The jig is highly reliable and easy to use. I recommend watching the inspirational You tube video series on how to build using these turnouts. I would like to see Fast Tracks offer a jig option to design the jig with independent ties as an alternative to using the QuickSticks. This would be consistent with the independent ties they offer.

John Dietrich (verified owner) –

Worked as described. It took me about 3 hours to buld my first turnout because I was going very slowly. But it worked great! I’m on #6, and down to 1.5 hours each. Follow the directions carefully and all will be well.

Mark Betzenheimer (verified owner) –

This is the second turnout fixture I've purchased (my first one in HO.) It works great. I couldn't be happier with it. I've already built 8 turnouts for a new layout, with more in the works.

Morgan Adams (verified owner) –

I stumbled across the Fast Tracks assembly fixture on an online search, and after watching the informative vids detailing each step of construction, I was a little intimidated - but game! I've now built several since getting the fixture a couple of weeks ago, and am extremely pleased with the results - and surprised how easy the learning curve has been. And as a bonus - it's a Canadian company!

Kenneth Farnham (verified owner) –

Bought the Code # 5 fixture, but was disappointed the fixture was designed to use only Micro-Rail and not a universal rail size. Although the site does mention Micro- rail and gives other that will work, for the first time buyer this is somewhat misleading, and not overly stated. I have built switches and use standard 83 rail and had stock available but the fixture was not useable for the items bought. Only the #5 Point Form filing jig could be used. A very expensive paper weight, and I will not purchase another item.

Tim Warris –

The brand of rail the fixture is designed to work with is literally right in the product name. - Fast Tracks

Joseph Aymar (verified owner) –

So far i built #5 (40 ) #6 (32) #8 curved (10) and double slip switches (4) Very reliable jigs. Great tutorials. Durable tools. Obviously saved a ton of money building my own.

Dwight Hall (verified owner) –

This jig takes all the guess work out of building turnouts. I have been building a large number of #5 turnouts to replace the English turnouts I have on my layout. They look amazing, and work so well, no additional wiring to make them work well with DCC.

Louis Nigro (verified owner) –

Bought the #5 after trying out the #6. Nicely built jif and the turnouts come out spot on.