Your cart is currently empty!

Made When Ordered

Production Time: 5 days

The AF-B-HO-ME70-C will be automatically added to our production queue when it is ordered.

PRICE : $187.54(USD)

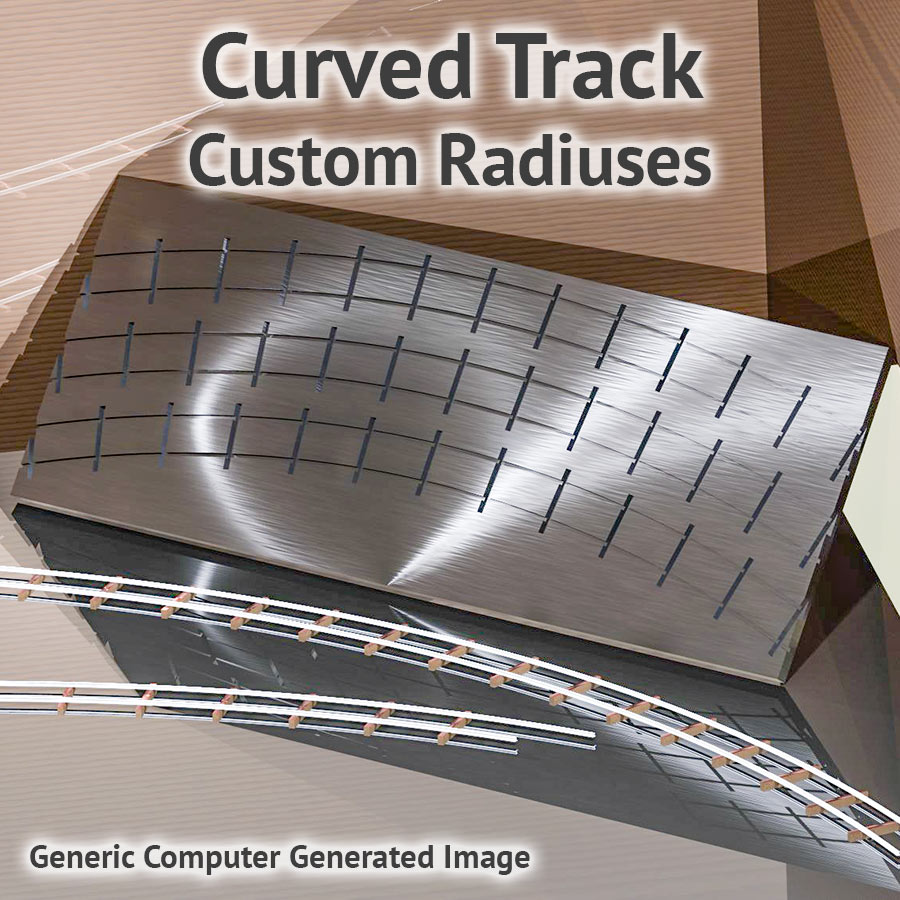

Can't find the exact radiuses that you need in any of our pre-defined curved track assembly fixtures? Not a problem! Enter the exact radius and track types (mainline, branchline, siding) that you need in the boxes above, and we will create a custom curved track fixture for your specific needs. Note that custom-built curved track assembly fixtures are premium priced, so you should try and order pre-designed curved track fixtures wherever possible.

Trackwork built using Fast Tracks fixtures is NMRA compliant and will easily out-perform any store bought track! No special skills are needed, and results are guaranteed. Fast Tracks assembly fixtures will help you build high quality hand laid track that:

- Is Highly Accurate - Build curved Custom trackwork that stays in perfect gauge - permanently

- Performs Perfectly - Eliminates track related derailments

- Is Easy To Build - No special skills are needed

- Looks Great! - Get results that rival even the most experienced modelers

- Lets You Work in Comfort - Build trackwork at your workbench

- Is NMRA Compliant - Will work with any NMRA compliant equipment

In addition to code 70 rail, you will also need to purchase matching 0.08" (2mm), (7 scale inches) thick, pre-gapped, HO CopperHead PC board Crossties manufactured by Fast Tracks for curved and straight trackwork. Our PC Board crossties match the thickness of the wood ties and are pre-gapped for DC and DCC compatibility.

Add our QuickSticks Crosstie Strips to your order to finish your trackwork. These laser-cut wood tie strips make finishing straight trackwork a snap! We also offer traditional single piece wood cross ties as well.

Using Fast Tracks tools and supplies, building curved trackwork is no different from building straight trackwork and does not require any special skills. The only real difference is that the rail needs to be pre-curved. To ensure that the rail is properly pre-bent, we highly recommend you consider including a Fast Tracks Rail Roller with your order. The Rail Roller tool will make it easy to create smooth, consistent curves and ensure that the rail is properly pre-bent to retain its shape over time.

Use the Fast Tracks RailRoller tool to pre-bend rail used in curved track fixtures.

Failure to pre-bend the rail for curved trackwork will result in solder joint failure over time!

Note: We reserve the right to add any custom-designed product to our standard product line using our regular pricing.

TIE SPACING SPECIFICATIONS

Standard Gauge

| Mainline | Branchline | Siding |

|---|---|---|

| 20" | 22" | 24" |

Narrow Gauge

| Mainline | Branchline |

|---|---|

| 22" | 24" |

Below is a cross-reference chart showing which rail other than Micro Engineering is compatible with our fixtures.

| Fixture Cut For | Rail Size | Compatible With |

|---|---|---|

| ME Code 55 | Code 55 | Atlas Code 80 |

| ME Code 55 | Code 55 | Atlas Code 55 |

| ME Code 55 | Code 55 | Peco Code 80 |

| ME Code 70 | Code 70 | ME Code 83 |

| ME Code 70 | Code 70 | Peco Code 83 (IL-115) |

| ME Code 70 | Code 70 | Peco 75 |

| ME Code 70 | Code 70 | Pilz Code 83 |

| ME Code 70 | Code 70 | Tilig 83 |

| ME Code 83 | Code 83 | ME Code 70 |

| ME Code 83 | Code 83 | Peco Code 83 (IL-115) |

| ME Code 83 | Code 83 | Peco 75 |

| ME Code 83 | Code 83 | Pilz Code 83 |

| ME Code 83 | Code 83 | Tilig 83 |

| ME Code 100 | Code 100 | Walthers Code 83 |

| ME Code 100 | Code 100 | Roco Line 83 |

| ME Code 100 | Code 100 | Atlas Code 83 |

| ME Code 100 | Code 100 | Atlas Code 100 |

| ME Code 125 | Code 100 | C & L 125 |

| ME Code 148 | Code 100 | Right-O-Way 148 |

You must be logged in to post a review.

| PARAMETER | VALUE | DETAILS |

|---|---|---|

| Rail Type | Micro Engineering Code 70 | |

| Tie Size (Model) | L - 1.17" (30 mm) W - 0.1" (3 mm) H - 0.08" (2 mm) | The actual size of the tie. |

| Tie Size (Prototype) | L - 8.5' (2.6 m) W - 9"(229 mm) H - 7" (178 mm) | The original tie size that the model was based on. |

| Track Gauge | 0.66" (17 mm) | The distance between the stock rails. |

| Size | L - 16.5" (419 mm) W - 6" (152 mm) H - 0.25" (6 mm) | The physical size of the product |

| Weight | 2.6 lbs (1.179 kg) | |

| Material | 6061 Aluminum |

Building A Turnout Switch Using Fast Tracks Tools

Step-by-step videos demonstrate how to build a complete switch using a Fast Tracks assembly fixture, PointForm, StockAid, and other tools.

Finishing Straight/Curved Track With QuickSticks

Watch as we demonstrate how to use our QuickSticks laser cut ties to finish straight and curved trackwork built in a Fast Tracks fixture.

Hand Laying Curved Track With Fast Tracks Tools

Hand laying smoothly curved trackwork can be challenging and tedious. Here we show you how Fast Tracks curved track assembly fixtures make it easy to build infinite lengths of perfectly formed curved trackwork right at your workbench.

Using The Multi-Brush Solder Paste Applicator For Soldering Trackwork

The Multi-Brush makes applying just he right amount of solder flux quick and easy. You will also find it a handy brush to have around for general model construction as well.

Using The 35W Weller Soldering Iron For Model Railroad Trackwork

Using the right soldering iron to solder trackwork is critical to success. We recommend the 35 watt Weller pencil type soldering iron with the ST7 conical shaped soldering tip. Watch along as we demonstrate how to get the most from this soldering equipment.

Bending & Straightening Rail With The Fast Tracks Rail Roller

Bending rail into long smooth curves for curved trackwork can be challenging. The Fast Tracks Rail Roller tool makes this difficult job quick and easy. Plus it can straighten bent rail as well. This video shows you how it works.

Solder Overview

Detail about the solder supplied by Fast Tracks for building all types of model trackwork.

Fast Tracks Video Channel

Visit our growing collection of track building demonstration videos

Fast Tracks Knowledge Base

In addition to an extensive Q&A section, we also offer a full library of track building documents.

Reviews

There are no reviews yet.